Warehouse Management System (WMS)

A warehouse management system (WMS) is a key part of the larger discipline of supply chain management. WMS software enables warehouses to control and direct all activities from receiving to shipping. This includes managing stock levels, optimizing picking routes, and directing labor resources.

WMS solutions are mission-critical for companies that rely on their warehouse operations for competitiveness. An efficient and effective warehouse operation can be the difference between a company that prospers and one that struggles.

The following are some of the benefits that a well-implemented WMS can bring to a business:

- Improved inventory accuracy – A good WMS will help to ensure that inventory records are accurate and up to date, which in turn will help to reduce stockouts and improve customer satisfaction.

- Improved order fulfillment – A WMS can help to optimize the order picking process, resulting in orders being fulfilled more quickly and accurately. This can lead to happier customers and increased sales.

- Improved space utilization – A WMS can help to reduce the amount of space required to store inventory, freeing up valuable space that can be used for other purposes.

- Improved labor utilization – A WMS can help to optimize the use of labor resources, resulting in reduced labor costs.

- Improved customer service – By improving inventory accuracy and order fulfillment, a WMS can help to improve customer service levels, leading to repeat business and increased sales.

Overall, a WMS is an essential part of running an efficient and effective warehouse operation. As such, it can be a powerful tool for driving profitability in today’s competitive business environment.

Related Links

What is warehouse management system (WMS)?

What is a Warehouse Management System (WMS)? – Interlake Mecalux

What is a Warehouse Management System (WMS)? – Next Level Storage

Related Videos

What is WMS?

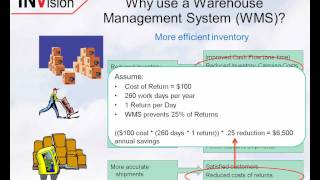

Why use a Warehouse Management System (WMS)?

Implementing a Warehouse Management System

-

What is WMS?

-

Why use a Warehouse Management System (WMS)?

-

Implementing a Warehouse Management System