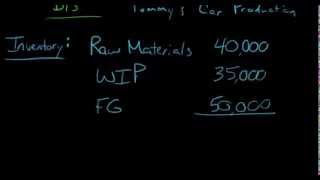

Work in Process (WIP)

Work in process, or WIP, refers to the inventory of unfinished goods that are currently in-transit or being processed by a company. In logistics, WIP is typically used to describe the materials and supplies needed for production and distribution processes. This can include:

- raw materials,

- partially completed products,

- and packaging materials.

The main purpose of work in progress is to improve efficiency and reduce costs by streamlining the manufacturing and shipping processes.

One challenge in managing work in progress is ensuring that it flows smoothly through production lines without any interruptions or delays. This requires careful planning and coordination between different departments within a company as well as with suppliers and customers. Another key concern when dealing with work in process is tracking changes in inventory levels so that they can be accurately reflected in financial statements. In general, companies with efficient logistics and inventory management systems tend to have lower costs and more satisfied customers.

While work in process is an essential part of running a successful business, it can also be one of the most challenging aspects to manage effectively. Whether you are responsible for managing WIP at a large manufacturing company or simply need to understand how it works, there are several key factors that you should consider when making decisions about this important inventory category. Some of the most important considerations include tracking inventory levels, planning production processes, optimizing logistics operations, and mitigating risks related to supply shortages. By taking these factors into account, you can help your organization implement effective strategies for improving productivity and profits in the long term.

Inventory management is a critical part of any business, but it can be especially challenging when dealing with work in process. WIP inventory consists of materials and products that are in the process of being completed, which can make it difficult to track and manage effectively. There are several key factors to consider when developing an effective inventory management strategy for work in progress, including:

- Tracking Inventory Levels: One of the most important aspects of managing WIP inventory is keeping track of levels throughout the production process. This information can be used to assess whether production is on schedule and identify potential problems that could impact delivery timelines.

- Planning Production Processes: In order to optimize efficiency, it is important to plan production processes carefully and ensure that materials are delivered in a timely manner. This requires coordination between different departments within the company, as well as with suppliers and customers.

- Optimizing Logistics Operations: Good logistics systems can help to minimize delays and improve overall efficiency in the manufacturing process, which reduces costs and helps to optimize operations on a broader scale.

- Mitigating Risks Related to Supply Shortages: A key risk to consider with WIP inventory is potential shortages of materials or finished goods, which could have serious impacts on production schedules and revenue targets if not adequately managed. By proactively assessing risks related to supply shortages, companies can develop effective strategies for mitigating these issues.

Work in progress inventory can be a challenge to manage effectively, but it is an essential part of running a successful business. By taking the time to understand the key factors involved in managing WIP, you can help your company optimize efficiency, reduce costs, and improve customer satisfaction. In the end, these benefits will result in increased profits and a competitive edge in today’s marketplace.

Related Links

Work in Process (WIP), What is WIP?

Work in process

Work-in-Progress (WIP) Definition

WIP — Work in Process — Definition & Example – InvestingAnswers

What is work in progress (WIP)?

Work in Process (WIP) Definition – Operations & Supply Chain Dictionary

Work In Process Financing – WIP Financing

Related Videos

Work in Process (WIP) Inventory

3 Types of Inventory (Raw Materials, WIP, and Finished Goods)

What is WORK IN PROCESS? What does WORK IN PROCESS mean? WORK IN PROCESS meaning & explanation

-

Work in Process (WIP) Inventory

-

3 Types of Inventory (Raw Materials, WIP, and Finished Goods)

-

What is WORK IN PROCESS? What does WORK IN PROCESS mean? WORK IN PROCESS meaning & explanation