Cube Out

Cube out occurs when a piece of equipment has reached its volumetric capacity before reaching the permitted weight limit. This situation often results in wasted space and inefficient utilization of assets. In order to avoid cube out, logistics professionals must carefully consider the dimensions of their shipments – or cubage – and plan accordingly.

There are many factors to consider when trying to avoid cube out. The type of product being shipped, the packaging materials used, and the size of the shipping container all play a role in determining the final dimensions of a shipment. By understanding these variables, logistics professionals can more effectively utilize their resources and avoid costly mistakes.

When shipping products that are not uniform in size or shape, it is important to use packaging materials that will allow for some flexibility. For example, using air pillows or foam peanuts can help to fill in any gaps and minimize the amount of wasted space.

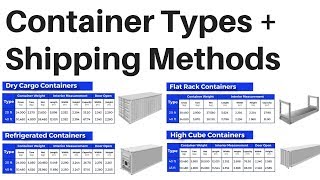

It is also important to select a shipping container that is appropriately sized for the cubage of the shipment. Oversized containers can be expensive and difficult to manage, while undersized containers can lead to cube out. By choosing the right container, logistics professionals can save time and money while ensuring that their shipments arrive intact.

In order to avoid cube out, it is essential to plan ahead and consider all of the variables involved in the shipping process. By taking these factors into account, logistics professionals can ensure that their shipments are properly packed and arrive at their destination in a timely manner.

Related Videos

Shipping Container Types LCL FCL Import Export Business Logistics Supply Chain International Trade

-

Shipping Container Types LCL FCL Import Export Business Logistics Supply Chain International Trade